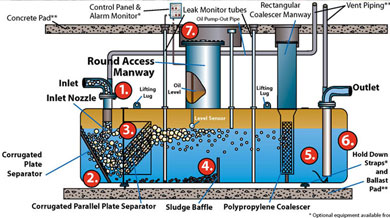

How PSI Separators Work

01

Inlet nozzle

Inlet and outlet piping enters the vessel through the top centerline of the separator per UL-58 requirements. This assures that the separator always operates full of liquid, thus utilizing the total volume of the vessel.

02

Corrugated parallel plate separator

Flow is directed towards a single corrugated plate at an angle perpendicular to the entrance pipe. This method of separation, known as the Buffalo- Morse Principle, serves multiple functions:

It reduces the velocity head of the incoming stream.

It spreads the flow out over the entire cross sectional area of the separator and prevents channeling of the flow.

The plate corrugations create sinusoidal flow patterns, which cause solids to break out of the flow stream and oil droplets to collide and coalesce.

03

Corrugated plate separator

The second stage of separation in the PSI separator is based upon the proven Royal Dutch Shell Principle of using multiple corrugated parallel plates. The parallel plate pack in the PSI oil-water separator consists of a special arrangement of heavy gauge removable corrugated steel plates.

04

SLudge baffle

The internal sludge baffle in the PSI separator serves two primary functions. First, solids are carried downstream in the separator by the internal hydraulics of the vessel where they collect in front of the sludge baffle. The baffle is located directly below the access manway for easy sludge removal from grade. Second, the sludge baffle directs the flow from the bottom quadrant of the separator towards the top of the vessel aiding in the floatation of small oil particles in the flow stream.

05

Polypropylene coalescer

PSI can provide, as an option, an additional polypropylene coalescer. This consists of a special matrix of polypropylene fibers designed to coalesce oil droplets down to 20 microns in size. An important addition to the PSI separator design is the use of a large coalescer access manway that spans the entire cross section of the coalescer and includes dedicated tracks for the coalescer.

06

Hold down straps

The outlet pipe is located at the end of the separator and draws clean water from the most quiescent section of the vessel. The effluent will contain a free oil and grease discharge of no more than 15 ppm in PS and PSR model separators and no more than 10 ppm in PSC and PSRC model separators.

07

Round access manway

PSI has the experience to provide solid state control systems to meet a wide variety of fluid level monitoring and flow control requirements including intrinsically safe liquid level sensors and custom-built control panels. Installing a high performance PSI separator to meet your discharge requirements along with a maintenance warning system will alleviate your wastewater treatment worries.